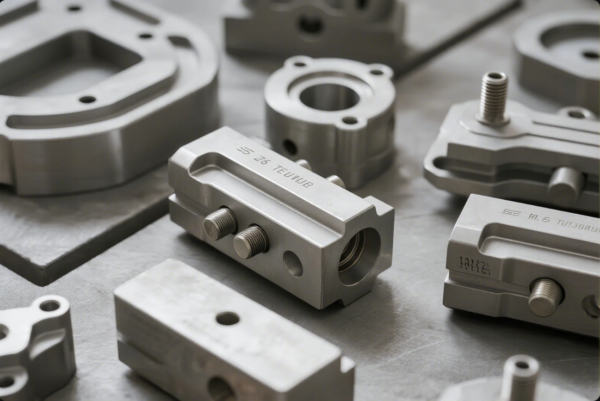

Why Use Plastic Instead of Metal?

Plastic is transforming modern manufacturing. It offers design freedom, corrosion resistance, and lower cost—all critical in today’s fast-paced industries.

Plastic materials are often chosen over metal for components requiring lightweight structure, complex geometry, and electrical insulation. They are easier to process and maintain in harsh environments.

In this article, we’ll explore practical reasons why many manufacturers are replacing metal with plastic—and when that switch brings real benefits.

Why Is Plastic Used Instead of Metal?

Many components don’t require the full strength of metal. In these cases, plastic provides a practical and economical solution.

Plastic is chosen for parts where weight reduction, resistance to rust, or ease of molding are essential. It performs well in applications where traditional materials may fail or be inefficient.

Where Plastic Works Best

| — | ||||||

|---|---|---|---|---|---|---|

| Electronics | Electrical insulation | ABS, PC | ||||

| Healthcare | Lightweight, safe | PE, PET | ||||

| Automotive | Fuel efficiency | PA6, PP | ||||

| Consumer Goods | Visual design variety | PS, HDPE |

A Prime client recently swapped aluminum mounts for nylon-reinforced parts. The outcome was a 38% cost saving with better corrosion performance.

What Is the Advantage of Plastic Over Metal?

Polymers offer functional and economic benefits that extend beyond initial production savings.

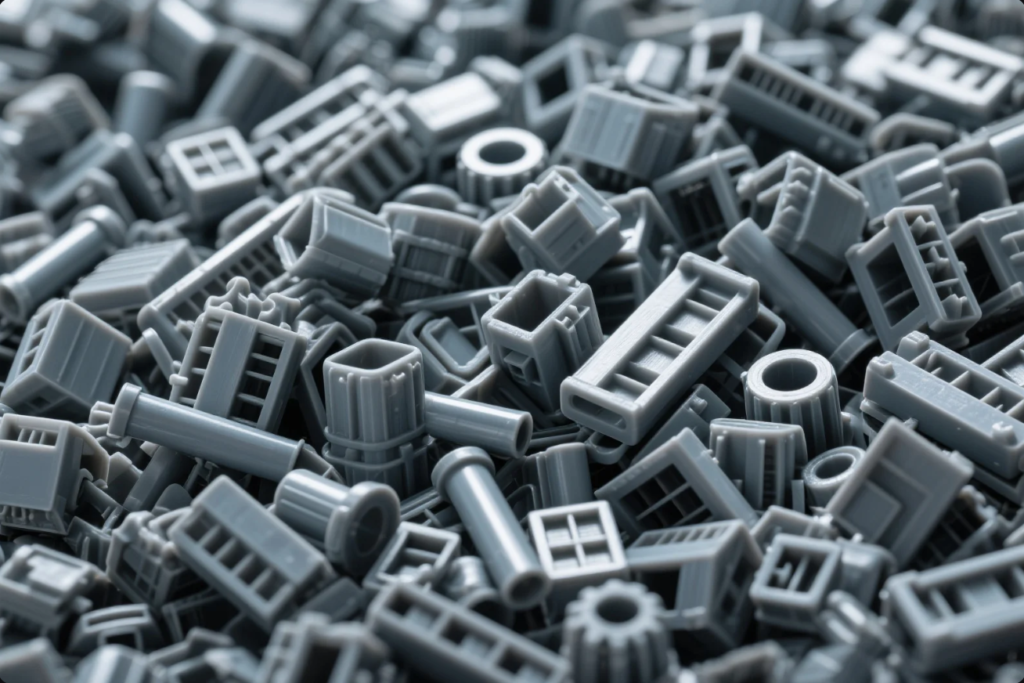

Plastics bring flexibility, lighter weight, chemical resistance, and better formability to applications where metal parts are more costly or difficult to manufacture.

Key Advantages of Polymer Solutions

- Up to 80% lighter than metal

- Built-in corrosion resistance

- Faster production cycles with injection molding

- Integrated part design with no need for welding

- Lower cost per part at high volume

In one telecom project, Prime produced polycarbonate switch boxes that reduced both installation time and material waste, replacing steel enclosures without compromise.

Is It Better to Use Plastic or Metal?

The choice depends on application demands. If the component must carry heavy load or endure high heat, metal still has its place.

Plastics are better suited for applications emphasizing reduced weight, environmental exposure, or compact production timelines.

| — | ||||||

|---|---|---|---|---|---|---|

| Weight | Significantly lighter | Heavy | ||||

| Corrosion Resistance | Naturally high | Needs coating | ||||

| Shape Design | Complex, flexible | Requires machining | ||||

| Thermal Insulation | Excellent | Conductive | ||||

| Processing Cost | Lower overall | Higher in small batches | ||||

| Recyclability | Thermoplastics can be reused | Some metals recyclable |

Prime’s engineers often work with clients to assess part geometry, function, and lifetime cost before recommending polymer conversion.

Why Is It Better to Use Plastic?

In many applications, plastic isn’t just sufficient—it’s superior.

Plastic excels in mass production, moisture resistance, and design efficiency. Its recyclability and weight reduction benefits make it a sustainable material in modern supply chains.

Use Cases Where Plastic Delivers More

- Precision electronics casings

- Moisture-proof enclosures in humid climates

- Snap-fit components in automotive dashboards

- Fire-retardant trays for telecom cable routing

For example, Prime helped a logistics client cut packaging weight by replacing metal storage clips with impact-resistant polypropylene, reducing shipping cost and assembly time.

FAQs

Q: Can plastic components last as long as metal ones?A: Yes, especially with engineering-grade materials like PEEK or reinforced PA66.

Q: Is plastic safe for industrial equipment?A: Absolutely. Many plastics meet UL and RoHS standards for electronics and electrical safety.

Q: How is plastic processed faster than metal?A: Plastic injection molding is quicker and more scalable than CNC or welding for complex geometries.

Q: Is plastic more eco-friendly?A: In many cases, yes—lighter weight reduces fuel usage, and modern thermoplastics are recyclable.

Q: What if I need help converting metal to plastic?A: Prime offers full support from material selection to custom tooling for plastic conversion projects.

Conclusion

Plastic opens new possibilities in design, manufacturing, and sustainability. When weight, complexity, or environmental conditions matter, it’s often the best material for the job.

Shandong Prime International Trade Co., Ltd. supplies high-performance plastic components that meet international quality standards and demanding project requirements.

📩 Email us at [email protected]🌐 Visit https://primecustomparts.com for expert consultation and free quoting.