A Complete Guide to Metal Fasteners: Types, Materials, and Applications in Modern Manufacturing?

Selecting the right metal fasteners is crucial for modern manufacturing. Mistakes can cause equipment failures, safety hazards, extra costs, or supply chain disruptions.

Metal fasteners connect and secure parts in every industry. This detailed guide covers all fastener types, materials, applications, certifications, sourcing strategies, trends, and expert answers to help you avoid costly mistakes. By following this guide, buyers can make smart decisions and partner with top suppliers like Prime.

If you want higher efficiency, longer product life, and peace of mind for your business, read on for proven solutions and real-world advice.

Table of Contents

- What Are the Main Types of Metal Fasteners Used in Industry?

- How to Choose the Right Material for Your Metal Fastener: Stainless Steel, Carbon Steel, or Brass?

- Key Applications of Metal Fasteners in Automotive, Construction, and Electronics

- International Standards and Quality Certifications for Metal Fasteners

- Industry Trends and Smart Sourcing Tips

- Frequently Asked Questions (FAQs)

- Contact Prime

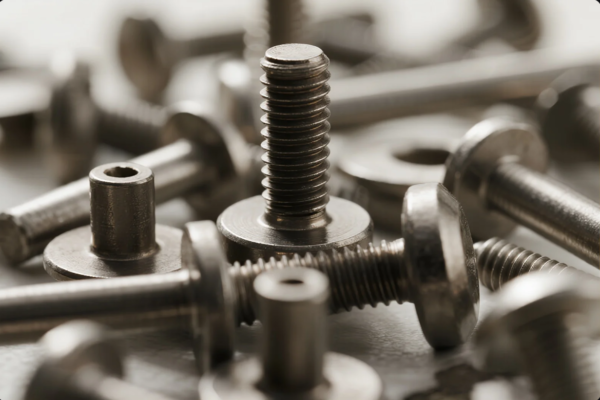

What Are the Main Types of Metal Fasteners Used in Industry?

Industrial buyers face a dizzying range of fastener types. Using the wrong type can damage machinery or put safety at risk. Correct fastener selection boosts production speed, reliability, and compliance.

The major types include bolts, screws, nuts, washers, rivets, anchors, studs, and pins. Bolts and nuts join thick parts and bear high loads. Screws are best for sheet or lightweight joining. Washers distribute load and prevent loosening. Rivets form permanent joints for structures like bridges and airplanes. Anchors connect to concrete or masonry. Studs provide alignment. Pins secure gears or rotating assemblies.

You can browse detailed diagrams and size charts at Bolt Depot and Fastenal. Würth Group and Bossard offer digital selection tools.

Deep Dive: Fastener Selection by Application

| Type | Key Function | Best For | Authoritative Source |

|---|---|---|---|

| Bolt | Heavy-duty joining | Construction, machinery | matmatch.com |

| Nut | Bolt securing | Automotive, energy | fastenal.com |

| Screw | Thin sheet or precise join | Appliances, electronics | mcfeelys.com |

| Washer | Load/stress distribution | Motors, bridges | boschrexroth.com |

| Rivet | Permanent connection | Aerospace, railways | stanleyengineeredfastening.com |

| Anchor | Concrete/masonry fixing | Building structures | hilti.com |

| Stud | Alignment, threaded join | Oil & gas, industrial | bossard.com |

| Pin | Locking, rotation | Engines, gearboxes | spirol.com |

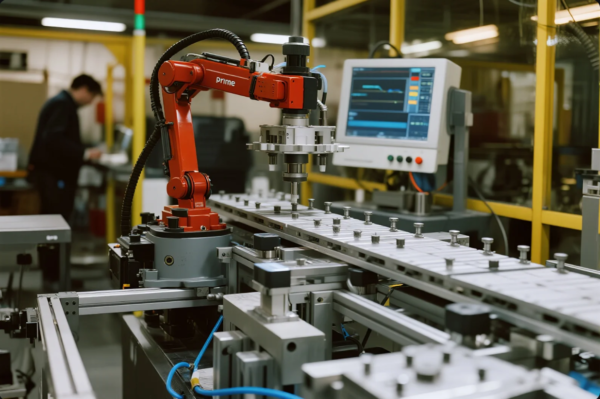

Modern fastener innovation also includes smart fasteners with embedded sensors, especially in Industry 4.0 applications.

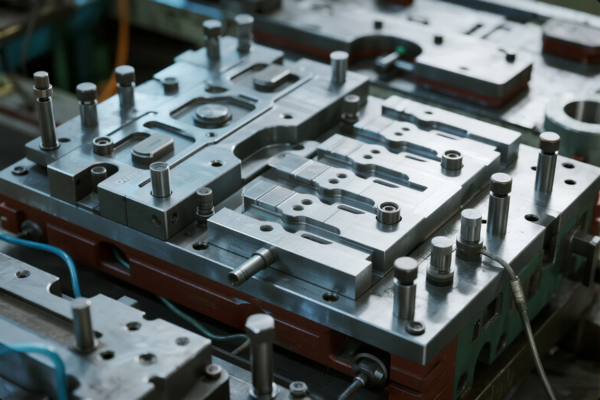

How to Choose the Right Material for Your Metal Fastener: Stainless Steel, Carbon Steel, or Brass?

Material selection is one of the most critical choices you will make. Choosing poorly causes rapid corrosion, high replacement costs, and even product recalls.

Stainless steel provides superior corrosion resistance, making it best for outdoor, marine, or medical uses. Carbon steel offers high strength at a lower price but needs coatings to resist rust. Brass conducts electricity, resists certain chemicals, and machines easily—ideal for electronics and plumbing. The right choice depends on your application’s strength, corrosion, and safety needs.

For more details, visit ASSDA, AZO Materials, and Copper Alliance. Check Total Materia for global metals databases.

Deep Dive: Fastener Material Science

| Material | Key Benefit | Typical Uses | Authoritative Link |

|---|---|---|---|

| Stainless Steel | Corrosion resistance | Marine, food, outdoor | outokumpu.com |

| Carbon Steel | Strength, price | Bridges, machines | totalmateria.com |

| Brass | Electrical, anti-rust | Electronics, plumbing | alro.com |

- Stainless steel grades: 304 is most common. 316 is needed for severe environments (Outokumpu’s guide).

- Carbon steel coatings: Galvanizing, zinc-plating, or black oxide extend service life (Fastener Mart).

- Brass in electronics: Used by leading suppliers like Bisco Industries.

Check ASTM for fastener material standards and SAE International for automotive grade info.

Key Applications of Metal Fasteners in Automotive, Construction, and Electronics

The world’s top manufacturers depend on reliable fasteners to meet safety codes, reduce liability, and boost product quality.

Automotive: High-tensile bolts and lock nuts resist vibration and extreme heat in engines and chassis. Construction: Structural bolts, anchors, and heavy washers prevent collapse and ensure code compliance. Electronics: Stainless and brass screws give precise, rust-free connections and avoid signal loss in sensitive devices.

Top auto references: Automotive World, Auto Bolt, Fastener Engineering.

Construction: Hilti, Construction Specifier, Roof Online.

Electronics: Electronics Weekly, TechDesign, ThomasNet.

Deep Dive: Industry-Specific Fastener Needs

Automotive

| Area | Fastener | Requirement | Authority |

|---|---|---|---|

| Engine | High-tensile bolts | Heat, vibration, safety | automotiveworld.com |

| Chassis | Lock nuts, washers | Anti-loosening, stability | fastenerengineering.com |

| Trim | Self-tapping screws | Fast, reliable installation | autobolt.net |

Construction

| Area | Fastener | Feature | Authority |

|---|---|---|---|

| Frames/Beams | Structural bolts | High loads, safety | constructionspecifier.com |

| Concrete/Masonry | Anchors | Secure fixing, reliability | hilti.com |

| Roofing | Sealing washers | Leak prevention | roofonline.com |

Electronics

| Area | Fastener | Feature | Authority |

|---|---|---|---|

| PCB | Brass screws | Conductivity, anti-rust | electronicsweekly.com |

| Housings | Stainless screws | Corrosion resistance | biscoind.com |

| Displays | Micro screws | Small size, precision | techdesign.com |

For interactive type/spec charts, see Bolt Depot and Bossard Selector.

International Standards and Quality Certifications for Metal Fasteners

Global buyers know certification is a must. Non-certified fasteners risk project failure, fines, and loss of business.

Top standards: ISO, DIN, ANSI, BS, JIS. ISO 898-1 and ISO 3506 cover strength and stainless properties. Legitimate suppliers like Prime provide all documents and pass customer audits. Always check with ISO’s member directory or TÜV Rheinland.

Main certification resources:

ISO, DIN, ASME, BSI Group, JISC

Deep Dive: Certification, Auditing, and Traceability

| Certification | What It Proves | Reference |

|---|---|---|

| ISO 9001 | Quality management | iso.org |

| ISO 14001 | Environmental compliance | iso.org |

| CE Mark | EU market conformity | europa.eu |

| RoHS | Hazardous substance limits | rohsguide.com |

| SGS | 3rd-party testing | sgs.com |

| Alibaba Verified | Supplier background | alibaba.com |

| TÜV Rheinland | Batch audits | tuv.com |

For packaging compliance and ideas, visit Packhelp and Sealed Air.

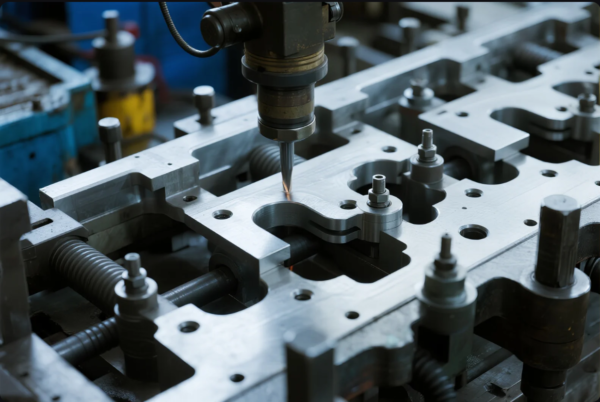

Industry Trends and Smart Sourcing Tips

Today, supply chains are global and digital. Buyers want traceability, speed, and strong compliance.

Leading companies use digital catalogs like Fastener Superstore, rely on Alibaba and ThomasNet for supplier vetting, and demand eco-compliance. Audited, certified, and responsive suppliers—like Prime—win repeat business.

Freight guidance: Maersk, DHL

Secure payment: Alibaba Trade Assurance

Inspection: Bureau Veritas

Stay up to date at SupplyChainDive, GreenBiz, Fastener World.

For technical specs, browse Amesweb, Engineering Toolbox, Bolt Science.

Smart Sourcing Checklist:

- Ask for all certifications and audit results.

- Verify international compliance.

- Review packaging before approval.

- Get digital photos and video audits.

- Ensure fast, clear communication.

Frequently Asked Questions (FAQs)

What’s the difference between a bolt and a screw?

Bolts need nuts; screws make threads in material. See Bolt Depot.

How do I check a supplier’s certificate?

Verify with ISO or Alibaba Verified.

Best material for anti-corrosion?

Stainless steel, explained at ASSDA.

Can I get packaging for retail or export?

Yes, explore Packhelp.

What industries require RoHS?

Electronics, automotive, home appliances. RoHS Guide.

How fast can Prime deliver?

Most orders ship in days—check Prime’s logistics.

What is an anchor fastener?

For concrete and masonry. See Hilti.

Are there digital selectors for fasteners?

Try Bossard Selector and Bolt Depot Chart.

How to avoid fake suppliers?

Check credentials at TÜV Rheinland and use Trade Assurance.

Where can I get technical data?

Try Engineering Toolbox.

Contact Prime

Ready to get a quote, technical advice, or expert fastener sourcing support? Contact Prime now for free consultation and a custom proposal.

- Website: https://primecustomparts.com/

- Email: [email protected]

We ship worldwide. We support ISO, DIN, and customer standards. We offer one-stop sourcing, fast delivery, and custom packaging—so you never miss a deadline.