How to Source Custom Metal Fasteners from China: Supplier Selection, Customization Options, and Quality Assurance?

Global industrial buyers know that the right fastener supplier can determine your project’s success or failure. Choosing a factory in China is a proven way to cut costs and get flexible customization, but only if you know how to avoid the common pitfalls.

In this comprehensive guide, you will learn the essential steps for selecting reliable metal fastener manufacturers in China, how to unlock advanced customization options, how to control quality at every step, how to manage the global supply chain, and why real case studies prove the value of working with the right partner. Each section contains actionable checklists and links to trusted industry resources to help you make better, faster sourcing decisions.

Read on to see how global leaders manage fastener sourcing, and get the knowledge you need to protect your brand and bottom line.

Table of Contents

- What Questions Should You Ask When Selecting a Metal Fastener Manufacturer?

- Customization Services for Metal Fasteners: Logo, Surface Finish, and Packaging Solutions

- The Role of Supply Chain Management in Fastener Procurement

- Case Study: Successful Custom Fastener Projects for Global Clients

- Frequently Asked Questions (FAQs)

- Contact Prime

What Questions Should You Ask When Selecting a Metal Fastener Manufacturer?

The foundation of every successful sourcing project is a rigorous supplier evaluation process. Relying on internet directories alone is risky—hidden trading companies, inconsistent quality, and poor communication are common complaints.

To avoid these headaches, create a checklist for supplier selection:

- Does the factory own and control its production lines, or are they a trading company? Request video tours and live calls. Use QIMA’s remote audits or Alibaba Verified Supplier to check ownership.

- Are they ISO 9001 or IATF 16949 certified? Confirm certificates on ISO’s database. Ask for the registration number and check with SGS or Bureau Veritas.

- Can they provide original test reports for every batch? Ask for mechanical and chemical data, ideally with third-party seals.

- What are their main export markets? Factories with experience serving North America, Europe, and Japan know international standards (DIN, JIS, ASTM).

- Do they accept third-party inspections? If they hesitate, walk away. Trusted firms cooperate with TÜV Rheinland, Intertek, or QIMA.

- What is their on-time delivery rate? Can they show past shipping documents, packing photos, and client references? For logistics proof, check Maersk, DHL, and FedEx.

- Do they have a clear, written quality complaint and replacement policy?

- Can they support English-language communication and technical drawing reviews?

Essential Domains for Supplier Search and Audit:

Alibaba, Made-in-China, Globalsources, ThomasNet

Deep Dive: Supplier Evaluation Matrix

| Audit Point | Key Details to Request | Trusted Source for Verification |

|---|---|---|

| Factory ownership | Company license, video | qcc.com, alibaba.com |

| ISO or IATF certificates | Registration number, scans | iso.org |

| Test reports (each batch) | PDF from lab, batch trace | sgs.com |

| Export experience | Past client, bill of lading | maersk.com |

| Online reviews | Customer testimonials | trustpilot.com |

| Third-party inspection | Contact info, cost | qima.com |

| Sample policy | Free/paid, lead time | primecustomparts.com |

Pro tip: For large projects, insist on a pre-production sample and a full Production Part Approval Process (PPAP).

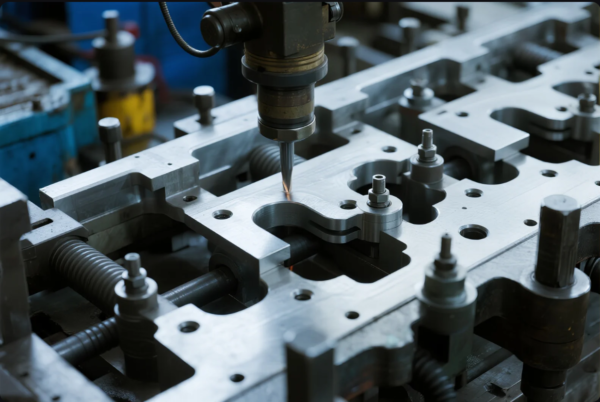

Customization Services for Metal Fasteners: Logo, Surface Finish, and Packaging Solutions

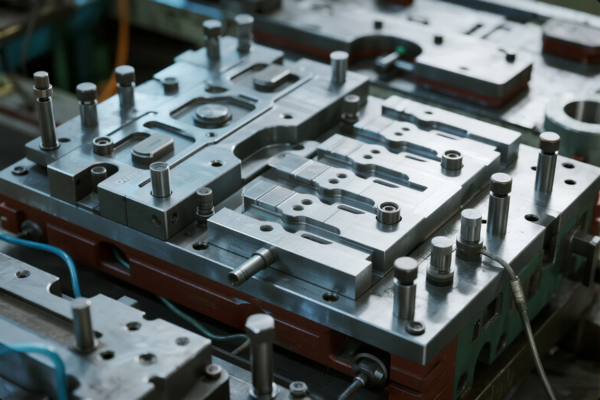

Leading factories in China can now deliver custom fasteners to exact customer specs, in both small and large batches. This creates strong branding, prevents counterfeiting, and helps with traceability through the global supply chain.

Customization options include:

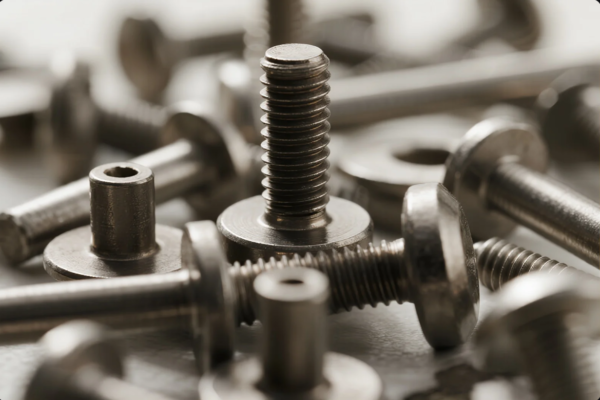

- Logo/Marking: Laser, dot-peen, or embossing on heads, shanks, or washers. Reference Engineering Toolbox’s bolt marking guide.

- Material Grades: Stainless (304/316), alloy steel, brass, titanium (matmatch.com), special low-carbon steels for welding, and anti-magnetic alloys for electronics.

-

Surface Finishes:

- Zinc plating (white/yellow/black) for rust prevention (AZO Materials)

- Hot-dip galvanizing for outdoor use (galvanizing.org.uk)

- Black oxide for mild corrosion and low glare (finishing.com)

- Chrome, nickel, anodizing, powder coating for aesthetic or technical use (thomasnet.com)

- Special coatings: PTFE for anti-stick, phosphate for paint prep

- Thread Customization: Metric, UNC/UNF, custom pitch, self-tapping, thread-locking features (boltdepot.com)

- Head Styles: Hex, socket, button, pan, countersunk, flanged, with or without slots for anti-tamper applications

- Color Coding: Colored coatings for quick identification in the field (thefabricator.com)

-

Packaging:

Examples:

Prime recently supplied automotive flange bolts with QR code marking for traceability and custom color-coded sets for a construction retailer in the EU. In electronics, anti-static packaging with customer logo is now standard.

The Role of Supply Chain Management in Fastener Procurement

Modern fastener supply chains depend on digital systems, real-time logistics, and rapid communication to prevent delays and shortages. Global disruptions make strong supply chain planning more important than ever.

Best practices include:

- Inventory Management: Factories with ERP systems (SAP, Oracle) and real-time tracking (NetSuite) can support Kanban, JIT, or scheduled releases.

- Batch Traceability: QR/barcode tracking on every box (GS1), digital photos, batch test results, and full production history for audits

- Shipping: Multiple transport modes (sea, air, rail, truck) with tracking via Maersk, DHL, FedEx, Kuehne+Nagel, Cainiao

- Export Compliance: CE, RoHS, REACH documents for Europe; ANSI/ASME for USA (ASME), and JIS for Japan

- Third-Party Inspection: SGS, Bureau Veritas, TÜV Rheinland, and QIMA for pre-shipment checks, material tests, and packing audits

- Risk Management: Safety stock, multi-vendor backup, force majeure policies, and regular supply chain reviews (SupplyChainDive, Logistics Management)

Advanced Supply Chain Practices

- EDI Integration: For large OEMs, use EDI for order automation (edibasics.com)

- Supplier Performance Dashboard: Track on-time rate, complaint rate, and cost trends (Kissflow Procurement Cloud)

- Real-Time Logistics: Every shipment with live GPS (Project44), digital PODs, and automated alerts

Case Study: Successful Custom Fastener Projects for Global Clients

Case 1: European Wind Power Construction

A German EPC contractor needed custom anchor bolts for wind turbine bases, with full EN 14399 certification, 10-year rust warranty, and QR-coded batch traceability. Prime’s engineers provided 2D/3D drawings, sample testing, and documented every batch with test reports. SGS witnessed the loading and packaging process. All shipments went by Maersk, tracked door-to-door. The customer’s project finished ahead of schedule.

Case 2: North American Heavy Truck Manufacturer

The client required more than 500,000 flange bolts, grade 10.9, with custom part number and logo marking. Strict IATF 16949 compliance was verified by TÜV Rheinland. FedEx air freight delivered samples in 3 days; the main order was shipped by sea, with NetSuite integration for PO tracking.

Case 3: Japanese Robotics OEM

A buyer ordered stainless M2 screws with black oxide and micro tolerance for assembly robots. Each lot included anti-static bags and ROHS/REACH test reports. DHL delivered samples for pre-assembly checks, and production photos/videos were shared throughout.

Why did these projects work?

- Direct engineering support, with rapid prototyping (Fictiv, Protolabs)

- Multi-level quality inspection (factory and third-party)

- Full transparency: digital tracking, live video updates

- Flexible MOQs and logistics choices

- Customer support for time zone, language, and market compliance

More examples are available at Prime’s case page.

Frequently Asked Questions (FAQs)

How do I find a real manufacturer, not a trading company?

- Check for in-house equipment photos, request video calls, and see if their business license matches their online listings. Use QCC or Alibaba Verified.

Can I get custom colors, finishes, or threads for small batches?

- Yes, many Chinese factories accept pilot runs and small orders thanks to digital manufacturing platforms (Fictiv, Xometry).

Is my data and design safe in China?

- Sign a bilingual NDA and use suppliers with a global client base. Secure document sharing via Dropbox or OneDrive.

How can I make payment securely?

- For samples, use PayPal. For bulk, use Alibaba Trade Assurance, T/T, or L/C (HSBC).

How do I ensure compliance with EU/US standards?

- Ask for CE, RoHS, REACH, and mechanical property reports. Confirm by third-party inspection (SGS).

What’s the usual lead time?

- For in-stock samples, 1–3 days by DHL. Custom projects: 2–5 weeks for production plus 1–4 weeks shipping.

Can I get digital technical drawings and production photos?

- Yes. Ask for CAD drawings (cadregister.com), full-size samples, and in-process photos for all orders.

Contact Prime

Ready to get a fast quote, technical consultation, or more information?

Contact Prime’s B2B export team for a real solution:

- Website: https://primecustomparts.com/

- Email: [email protected]

Prime’s ISO-certified factory ships worldwide and delivers one-stop custom fastener solutions for every industry, every market. Let us handle your next project with speed, transparency, and confidence.