What Materials Can Be Used for Laser Cutting?

Laser cutting materials often confuse buyers.

Laser cutting supports metals, plastics, woods, and composites. Some materials like PVC are unsafe. Always verify compatibility.

Some materials look ideal but perform poorly. Keep reading to avoid costly mistakes and choose the right materials.

Table of Contents

- What materials are suitable for laser cutting?

- What material cannot be laser cut?

- What is the best surface for laser cutting?

- Is plywood or MDF better for laser cutting?

- Conclusion

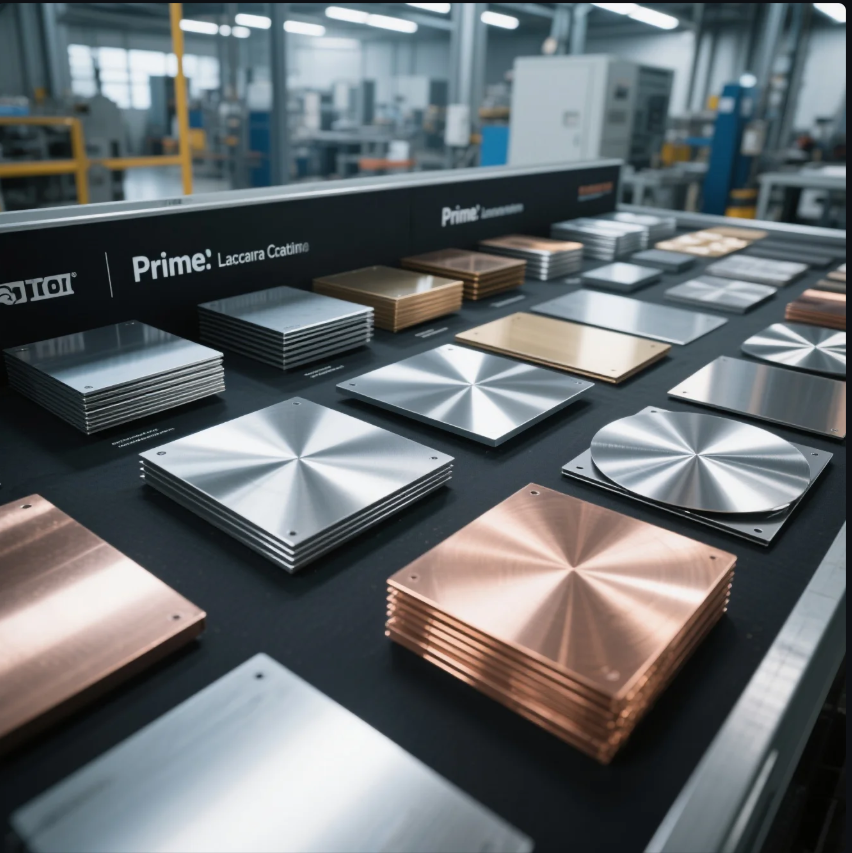

What materials are suitable for laser cutting?

Many buyers struggle with choosing compatible materials.

Laser cutting works best with carbon steel, stainless steel, aluminum, acrylic, MDF, and plywood. These materials offer clean edges.

Laser cutting is one of the most efficient ways to produce precision parts at scale. It supports a wide range of metals and non-metals. At Prime, we handle high-volume production using laser cutting across ten in-house production lines. We focus on delivering tight tolerances and clean edges, whether you need complex custom CNC parts or decorative metal stamping parts.

Which metals work best for laser cutting?

Let’s start with metal-based materials. These are the backbone of many B2B industrial components:

| Material | Thickness Range | Surface Finish | Application Use |

|---|---|---|---|

| Carbon Steel | 0.5–25 mm | Matte/Clean | Brackets, frames, base structures |

| Stainless Steel | 0.5–20 mm | Bright finish | Food-grade parts, medical equipment |

| Aluminum | 0.5–15 mm | Reflective | Lightweight machine parts |

Laser cutting is highly effective for metals with uniform density. Stainless steel needs proper calibration due to its reflective properties. Carbon steel offers the most flexibility. Aluminum, though lightweight, requires strict heat management due to its conductivity.

At Prime, we use CNC-controlled laser systems that auto-adjust settings for each material. This helps us deliver burr-free edges and precise kerf width. Many overseas clients rely on us because we deliver ISO-certified quality on every batch, regardless of material complexity.

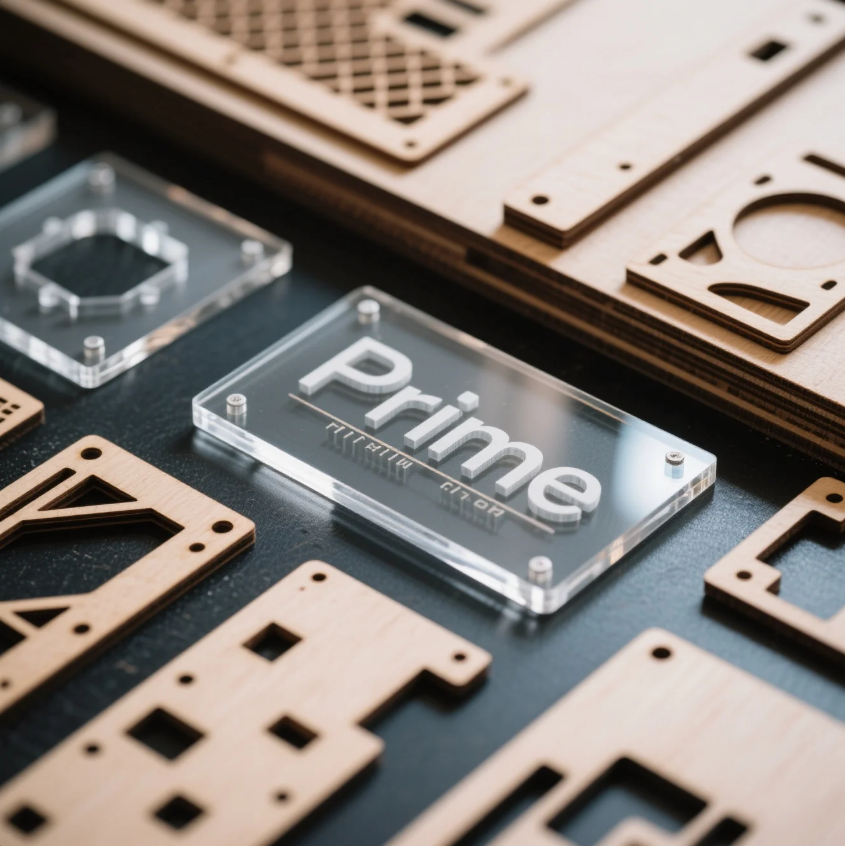

What about plastics and wood?

Laser cutting is not limited to metals. In fact, it's one of the cleanest and most accurate ways to process plastics and engineered wood.

These are the most requested non-metallic materials:

- Acrylic (PMMA) – used for signage, light panels, product display stands

- MDF – ideal for decorative wall panels, models, and indoor furniture parts

- Plywood – commonly used in jigs, tool boards, furniture frames

- Delrin (POM) – excellent for precision moving parts, bushings

- PETG & Mylar – used in electronics housings and lightweight packaging

We recommend laser over mechanical routing for plastic when the goal is speed and edge smoothness. At Prime, we deliver both small prototypes and full production runs with consistent results. Our engineers can also advise you on material substitutions if your selected material isn’t ideal for laser use.

Explore more in our laser cutting materials overview.

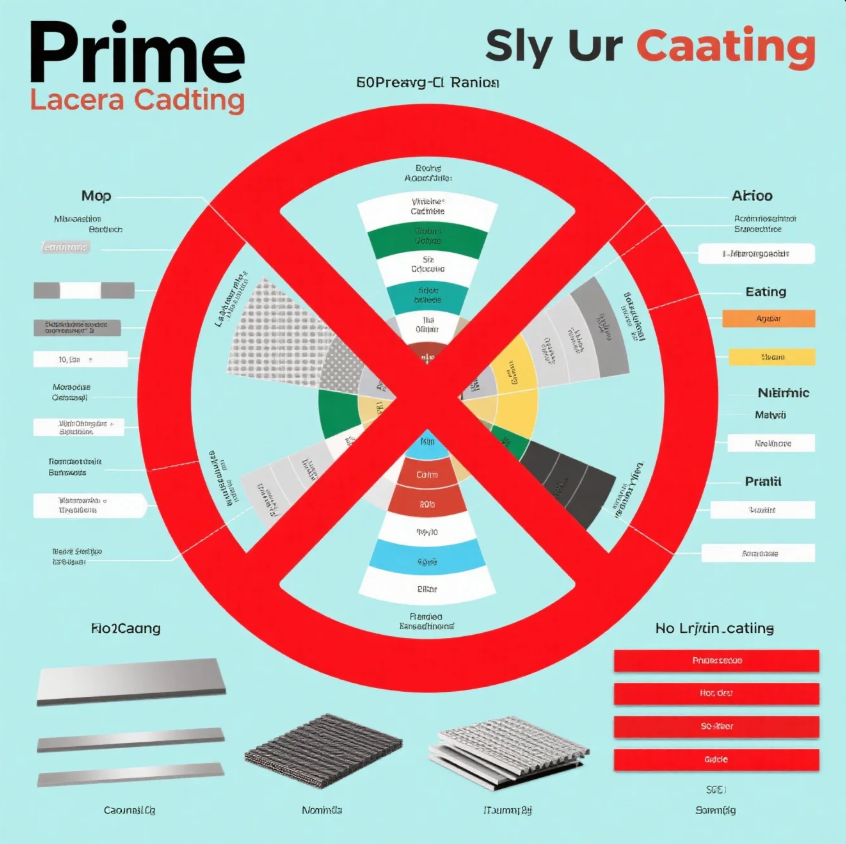

What material cannot be laser cut?

Some materials may look cuttable, but actually pose safety and equipment risks.

PVC, polycarbonate, ABS, and fiberglass should be completely avoided. They pose health and equipment hazards.

Laser cutting involves intense localized heat. When certain plastics are cut, they release toxic fumes that can harm operators or corrode equipment. In some cases, the material doesn’t cut—it melts and leaves burnt residue on the lens or optics.

| Material | Can Be Cut? | Hazard |

|---|---|---|

| PVC | ❌ | Chlorine gas, corrodes optics |

| Polycarbonate | ❌ | Melts instead of cuts cleanly |

| ABS | ❌ | Cyanide-based fumes when burnt |

| Fiberglass | ❌ | Glass fiber scatters light |

| HDPE/LDPE | ⚠️ | Melts, often catches fire |

| Polypropylene | ⚠️ | May warp, cut inconsistently |

How Prime ensures material safety

Every material that enters our factory is checked against our internal cutability chart. We test edge responses on sample sheets before production. This protects both your products and our machinery. Our customers rely on this assurance when sourcing casting parts, plastic components, and hybrid assemblies.

For a full banned material list, view our laser cutting safety guide.

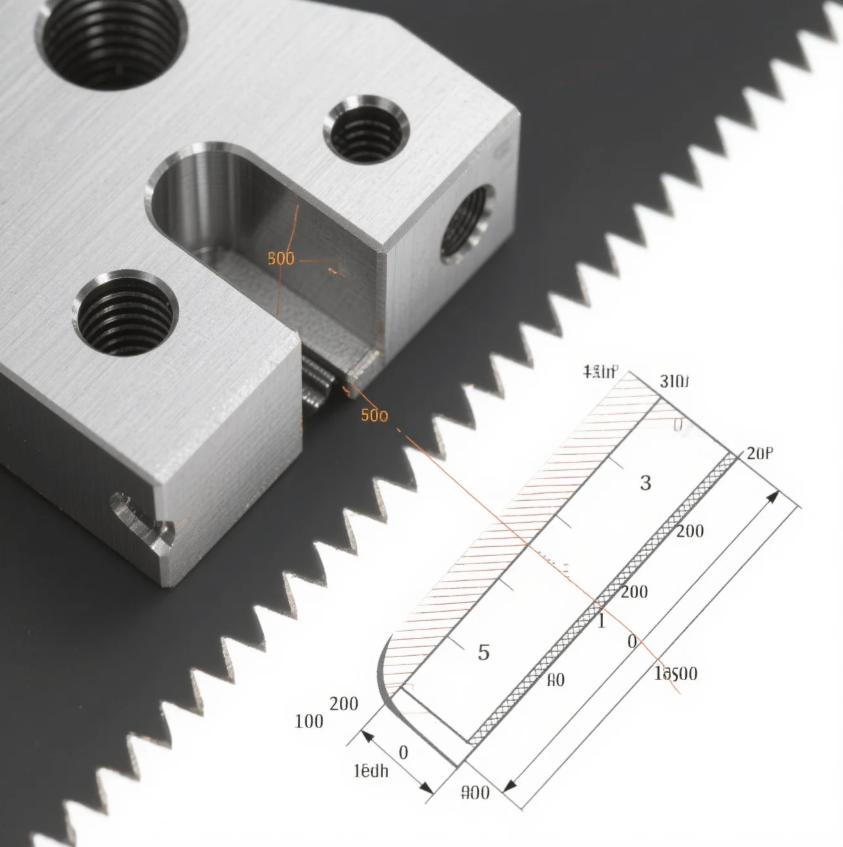

What is the best surface for laser cutting?

Surface condition affects cut quality more than you may think.

Smooth, flat, and non-reflective surfaces yield the cleanest, most consistent cuts. Avoid glossy or warped sheets.

Laser cutting relies on beam consistency. If your material has coatings, gloss, or warping, the beam may reflect or scatter. That results in uneven kerf lines, burns, or even incomplete cuts.

| Surface Condition | Cut Quality | Risk Factor |

|---|---|---|

| Matte Carbon Steel | ✅ High | Excellent absorbency |

| Anodized Aluminum | ✅ Moderate | Better than raw aluminum |

| Galvanized Sheet Metal | ❌ Poor | Coating fumes, uneven burn |

| Glossy Plastic Sheet | ⚠️ Inconsistent | Melts edges, warps parts |

How Prime maintains surface quality

At Prime, we use pre-brushed metal stock or sanded finish sheets when needed. We also store sheets in temperature-controlled rooms to avoid moisture warping. When our clients order fasteners or chassis plates, they receive uniform quality every time.

If you are unsure whether your material is suitable, we offer free consultations. We'll help you determine the optimal sheet finish before cutting begins.

Visit our laser cutting surface guide for more.

Is plywood or MDF better for laser cutting?

Both MDF and plywood are popular and affordable—but they behave differently under a laser.

MDF gives smooth, predictable results. Plywood resists stress and warping better.

Choosing between MDF and plywood depends on your project needs.

| Feature | MDF | Plywood |

|---|---|---|

| Consistency | High (engineered particles) | Varies (depends on layers) |

| Burn Quality | Clean, even | May vary due to glue/resin |

| Structural Strength | Weak | Strong |

| Weight | Heavier | Lighter |

| Cost | Lower | Slightly higher |

| Engraving Detail | Very precise | Slightly rougher |

When to choose MDF?

- Fine engraving needed

- Large sheet designs with minimal load

- Lower production cost

- Better surface painting or lamination

When to choose plywood?

- You require strength and durability

- The part will be bolted or stressed

- You want natural wood grain appearance

- Humid environments or semi-outdoor use

At Prime, we run test cuts for both MDF and plywood before confirming mass production. You can request samples to evaluate engraving depth, cut edge charring, and structural behavior. Our packaging team also crates wood-based orders with internal padding, so your delicate sheets arrive safely.

Need a combined solution, like plastic-backed plywood or fastener inserts in MDF? We can help. Our engineers design assemblies using laser-compatible substrates for better durability and assembly ease.

Conclusion

Choose safe, laser-friendly materials for clean cuts and safe results.