When to Laser Cut vs 3D Print?

If you’ve ever asked yourself: “When to laser cut vs 3D print?”—you’re not alone.

Laser cutting and 3D printing are two of the most used processes in modern manufacturing. But each fits very different needs.

Knowing exactly when to laser cut vs 3D print will save you time, reduce cost, and improve your product’s performance.

Table of Contents

- Should I get a laser cutter or a 3D printer?

- What are the advantages of laser cutting over 3D printing?

- What is the main disadvantage of laser cutting?

- What plastics cannot be laser cut?

- Conclusion

Should I get a laser cutter or a 3D printer?

Understanding when to laser cut vs 3D print starts with your part’s geometry and function.

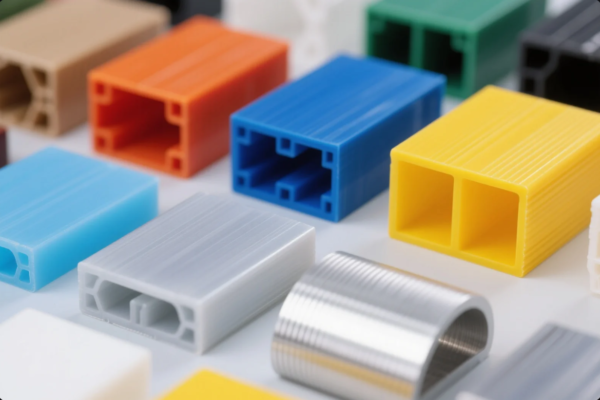

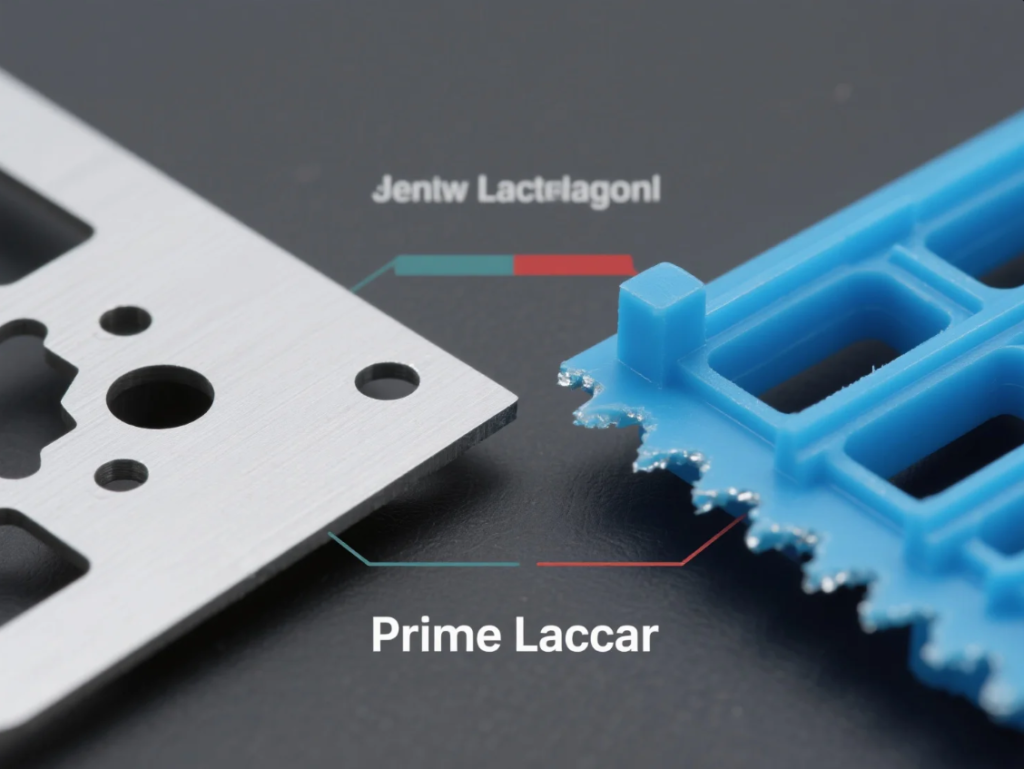

Laser cutting is best for 2D outlines. 3D printing is ideal for shapes with volume and detail.

| Example Product | Better Process | Why it matters |

|---|---|---|

| Steel mounting plate | Laser cutting | Flat, fast, repeatable |

| Curved plastic casing | 3D printing | Internal volume, complex walls |

| Acrylic signage | Laser cutting | Clean edges, engraved detail |

| Sensor housing prototype | 3D printing | Functional, custom geometry |

Still not sure when to laser cut vs 3D print? At Prime, we review files and advise the most cost-efficient method—whether you need 10 parts or 10,000.

What are the advantages of laser cutting over 3D printing?

If you're thinking about when to laser cut vs 3D print, speed and edge quality often make the decision easy.

Laser cutting offers unmatched speed, perfect edge finishes, and lower per-part cost for flat parts.

| Feature | Laser Cutting | 3D Printing |

|---|---|---|

| Speed | Seconds per part | 30 min–6 hrs per part |

| Post-processing | None needed | Supports must be removed |

| Surface finish | Smooth edges | Visible layer lines |

| Batch production | Very efficient | Slower with quantity |

Laser cutting wins when:

- Parts are flat and have high volume

- You need clean visuals like logos or cutouts

- You want low per-unit cost

- You require ISO-level repeatability

At Prime, we use laser cutting for thousands of metal and plastic parts weekly—always checking if it’s better than 3D printing in cost or speed.

What is the main disadvantage of laser cutting?

To decide when to laser cut vs 3D print, you must also understand the main disadvantage of laser cutting.

Laser cutting is limited to 2D outlines and can’t produce complex 3D features or hollow structures.

Other common limitations include:

- Heat-affected edges on soft materials

- Difficulty cutting highly reflective surfaces

- No internal geometry (pockets, threads, voids)

So, the main disadvantage of laser cutting is lack of dimensional flexibility. In contrast, 3D printing easily builds in curves, overhangs, and internal features.

When clients ask us when to laser cut vs 3D print, we always consider whether a 3D structure is essential—or if a 2D profile will do the job better.

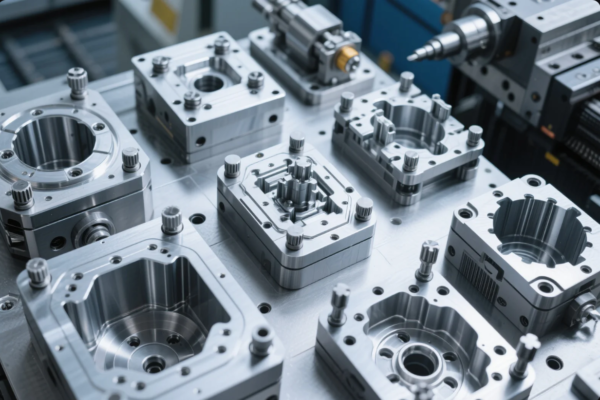

We often combine laser-cut parts with CNC machining or printed add-ons to overcome these challenges.

What plastics cannot be laser cut?

Another key issue in when to laser cut vs 3D print is material safety.

Certain plastics cannot be laser cut because they emit toxic gases or damage optics.

Plastics that cannot be laser cut:

| Material | Why it's unsafe |

|---|---|

| PVC | Emits chlorine gas |

| ABS | Produces cyanide-based fumes |

| Polycarbonate | Melts instead of cuts cleanly |

| Fiberglass | Damages lenses, causes stray sparks |

At Prime, we review every material and reject any plastic that cannot be laser cut safely. We also offer laser-safe alternatives like acrylic, PETG, and Delrin.

✅ You can find our full approved material list on the Prime site.

So, when to laser cut vs 3D print also depends on what you're cutting. If you're working with plastics that cannot be laser cut, 3D printing may be your only safe option.

Conclusion

When to laser cut vs 3D print? Use laser cutting for speed, edge quality, and 2D efficiency. Use 3D printing for 3D geometry, enclosures, and prototypes.

Still unsure when to laser cut vs 3D print?

Let Prime help you decide with a free consultation and file review.

- ✉️ Email: [email protected]

- 🌐 Website: https://primecustomparts.com

Whether you're dealing with laser-cut plastic, 3D printed prototype, or combining both, we’ll help you get the most efficient solution.