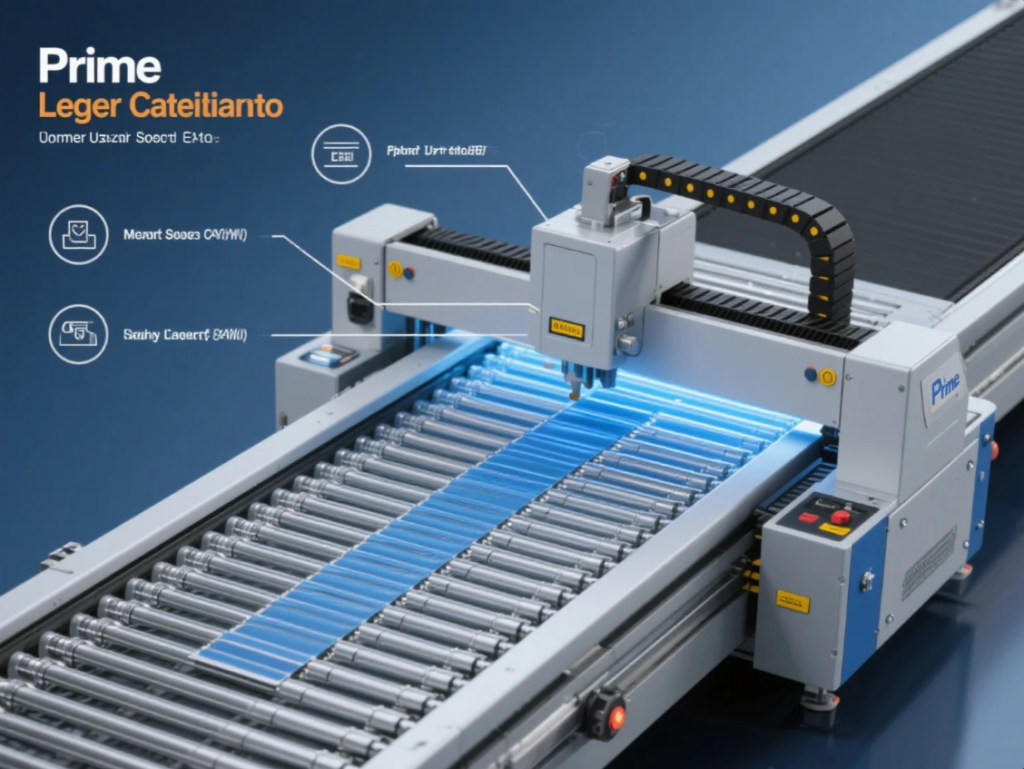

Is Laser Cutting Faster Than CNC?

Speed matters in modern manufacturing—and many clients ask: Is laser cutting faster than CNC?

Yes. Laser cutting is generally faster than CNC machining when cutting flat sheets. Especially for 2D outlines, laser offers higher speed and better repeatability.

But speed isn’t everything. This guide explains when laser wins, where CNC still dominates, and how Prime helps you choose the right tool.

Table of Contents

- Is laser cutting better than CNC?

- What is the main disadvantage of laser cutting?

- What is one advantage of a laser cutter over a CNC router?

- Is laser cutting fast?

- Conclusion

Is laser cutting better than CNC?

Some clients assume laser cutting is just a “light version” of CNC. Not quite.

Laser cutting is better for thin-sheet parts that need fast, accurate 2D profiles. CNC is better for deep pockets, threads, and 3D surfaces.

Comparison table:

| Feature | Laser Cutting | CNC Machining |

|---|---|---|

| Speed (2D shapes) | Very fast (seconds per part) | Slower (minutes per part) |

| Surface finish | Smooth edge, no burrs | Variable, needs post-polish |

| Material flexibility | Excellent for metal, plastic sheets | Works with blocks, castings, rods |

| Tool wear | None (non-contact) | High (cutting tools degrade) |

| Setup time | Fast (just a DXF or STEP) | Slower due to toolpath programming |

At Prime, we use both daily. For flat brackets, gaskets, and shims—laser always wins. But for milled slots, counterbores, or tapped holes—CNC is the way to go.

Still deciding between laser and CNC? We’ll review your design and recommend the faster, cheaper method.

What is the main disadvantage of laser cutting?

Laser is fast and precise—but no process is perfect.

The main disadvantage of laser cutting is its limitation to 2D shapes and sensitivity to reflective or thick materials.

Common limitations:

- Cannot mill pockets or threads

- Not ideal for copper or brass (reflects beam)

- Causes burn marks on soft materials like MDF or PETG

- Max thickness typically \~25mm for steel

- May require ventilation for fume-heavy materials

| Disadvantage | Affects | Suggested Solution |

|---|---|---|

| No depth or 3D features | Part geometry | Use CNC or combine post-process |

| Reflective material issues | Optics and cut consistency | Use coated or matte materials |

| Heat-sensitive surfaces | Edge finish | Reduce power or use air assist |

At Prime, we often combine both: laser cut the 2D shape, then CNC drill and tap after. This hybrid workflow gives you the best of both methods.

Understanding the main disadvantage of laser cutting helps you avoid bad cuts, rejects, and downtime.

What is one advantage of a laser cutter over a CNC router?

The answer is speed—but also edge quality.

One key advantage of a laser cutter over a CNC router is the clean, polished edge it produces—without any physical contact or tool wear.

Laser beams cut by melting or vaporizing material. Routers use spinning bits, which wear down and leave tool marks.

Why this matters:

- Laser cuts clean through acrylic—CNC may crack it

- Laser doesn’t leave tool burrs

- Laser kerf is narrower (more precise for tight outlines)

- Laser systems have fewer moving parts, so maintenance is lower

At Prime, we often cut acrylic display panels, nameplates, and metal enclosures with laser—because CNC routing would take longer, cost more, and require finishing.

This advantage makes laser ideal for plastic parts, signage, packaging layers, and more.

Is laser cutting fast?

In a word: Yes.

Laser cutting is one of the fastest ways to process flat materials, especially in high volume.

Typical cut speed examples:

| Material | Thickness | Average Cut Speed |

|---|---|---|

| Stainless Steel | 1.5 mm | 30–50 mm/sec |

| Aluminum | 2 mm | 40–70 mm/sec |

| Acrylic | 3 mm | 50–80 mm/sec |

| Mild Steel | 5 mm | 20–35 mm/sec |

Our laser systems use nesting software to minimize waste and maximize throughput. We cut hundreds of parts per hour—sometimes thousands per shift.

Need fast delivery? Prime offers next-day cutting for in-stock sheet parts.

And because there's no tool wear or complex fixture setup, laser starts faster than CNC—especially on new projects or prototypes.

Conclusion

So, is laser cutting faster than CNC? Yes—for flat parts, laser offers better speed, edge quality, and lower setup cost.

Need advice on which process is right for your part?

Contact Prime for expert review, quote, and fast turnaround.

- ✉️ Email: [email protected]

- 🌐 Website: https://primecustomparts.com

Whether it’s laser-cut sheets, CNC-machined prototypes, or a custom hybrid—we help global buyers move faster, safer, and smarter.

One Response

good good