What Is Better Than Laser Cutting?

Laser cutting is one of the most widely used cutting methods today—but it isn’t always the most suitable.

In certain cases, other methods like waterjet, plasma, or CNC machining offer better performance, material compatibility, or cost savings.

At Prime, we analyze each project based on geometry, volume, precision, and material type to recommend the ideal process.

Table of Contents

- What is the alternative to laser cutting?

- Is waterjet cutting cheaper than laser cutting?

- Is plasma cutting better than laser?

- Which is better, CNC or laser?

- When does Prime combine methods?

- Conclusion

What is the alternative to laser cutting?

There are four reliable substitutes depending on your part’s material, thickness, and design:

- Waterjet cutting

- CNC machining

- Plasma cutting

- High-volume stamping

| Process | Best Use Case | Notable Strength |

|---|---|---|

| Waterjet | Heat-sensitive or thick materials | No heat-affected zone |

| CNC | Parts with internal features or depth | 3D shape and threaded holes support |

| Plasma | Fast steel cutting for rough tolerances | High-speed, low-cost |

| Stamping | Mass production of flat metal parts | Consistency, speed, low unit cost |

More on CNC options and metal stamping at Prime.

🔗 Related resource: ThomasNet – Overview of Industrial Cutting

Is waterjet cutting cheaper than laser cutting?

Waterjet can cut nearly any material, but it's not typically the most budget-friendly.

While extremely versatile, waterjet systems often have higher hourly costs due to abrasive material use, maintenance, and slower speed.

| Factor | Laser Cutting | Waterjet Cutting |

|---|---|---|

| Hourly Cost | \$60–\$120 | \$100–\$200 |

| Cut Accuracy | ±0.1 mm | ±0.2 mm |

| Material Support | Metals, plastics, acrylic | Anything (metal, stone, glass) |

| Cleanup Required | Minimal | High (wet + slurry) |

Use waterjet when:

- You must avoid heat distortion

- Cutting composite or fragile materials

- Working on very thick plates or tiles

See this OMAX comparison guide for more.

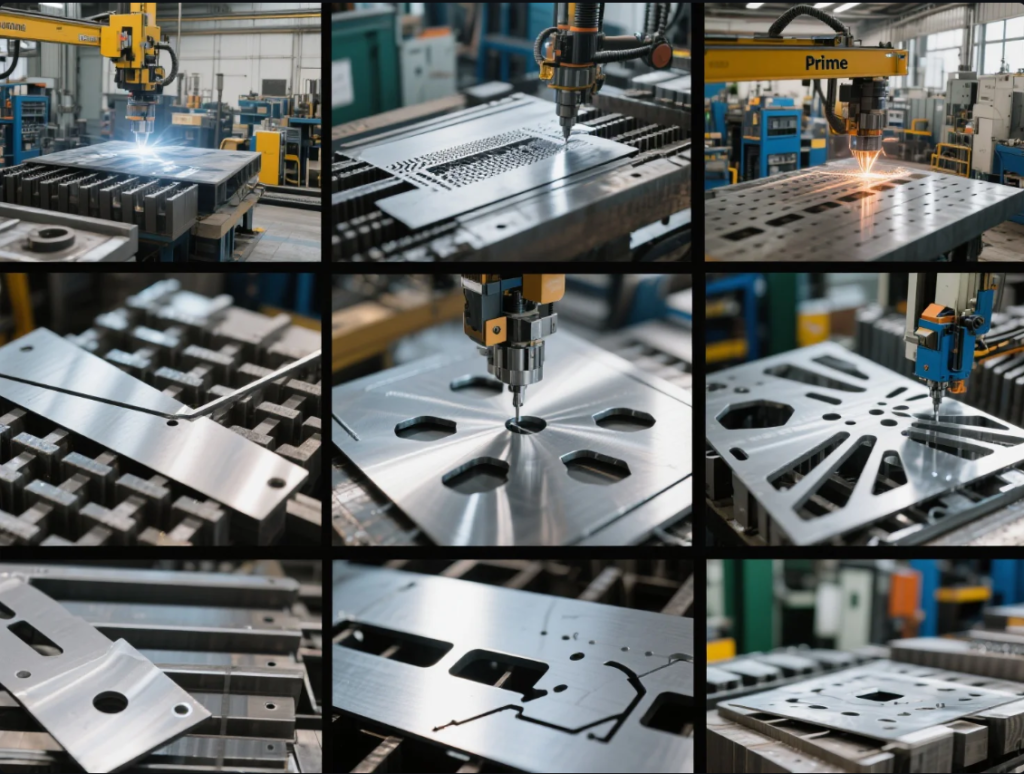

Is plasma cutting better than laser?

Plasma systems excel in specific industrial environments where speed and power are priorities over detail.

They are ideal for slicing thick steel plates fast but cannot match the precision of laser equipment.

| Feature | Plasma | Laser |

|---|---|---|

| Speed | Very fast | High but material-specific |

| Edge Smoothness | Rough, dross may remain | Smooth, burr-free |

| Max Thickness | Up to 100mm steel | Usually ≤25mm |

| Application | Structural steel, beams | Machine parts, thin sheets |

Laser remains preferred for parts where visual appearance, edge tolerance, or engraving is important.

Related: Trotec’s Plasma vs Laser Comparison

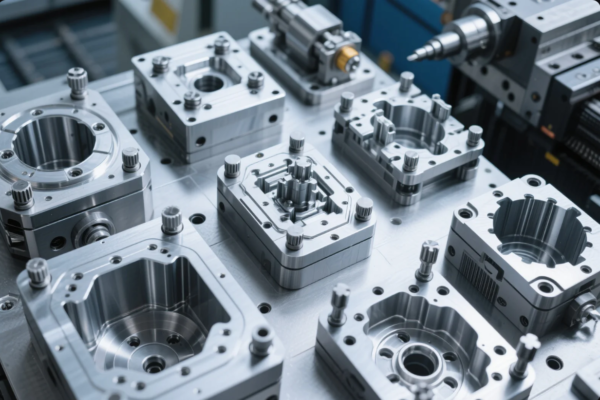

Which is better, CNC or laser?

This depends entirely on part shape, material, and required detail.

CNC machines are better when pockets, threads, and 3D forms are needed. Laser cutters dominate in fast 2D profiling.

| Process | Ideal For | Limitations |

|---|---|---|

| CNC Machining | Deep features, threads, cutouts | Slower setup, tool wear |

| Laser Cutting | Flat sheets, labels, fast patterns | No depth control |

For example, we often laser cut aluminum enclosures, then drill holes and apply threads using CNC centers.

📘 Full comparison: Xometry – CNC vs Laser

When does Prime combine methods?

In many projects, we optimize production by blending technologies:

- Laser for fast outer contours

- CNC for threads and holes

- Stamping for volume production

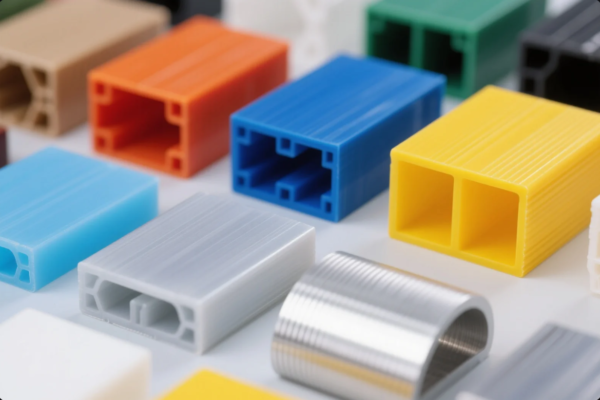

- Plastic injection or casting for functional parts

Example: For a client producing 5000+ ventilation panels, we:

- Laser cut base outline (±0.1mm)

- CNC-mill airflow grooves

- Form with dies + apply powder coat

- Pack with export-ready industrial packaging

This approach reduces unit cost and improves turnaround time—especially for clients in the EU and North America.

Conclusion

Each cutting process offers its own strength. While laser remains a great all-around tool, alternatives like waterjet, plasma, or CNC may suit specific jobs better.

Let Prime help you evaluate the best option for your project’s cost, speed, and quality goals.

Need help choosing the most efficient process for your next project?

Get in touch with Prime for professional guidance, DFM review, and fast quoting.

- ✉️ Email: [email protected]

- 🌐 Website: https://primecustomparts.com

Whether you need laser-cut sheets, CNC-machined blocks, or hybrid precision parts, Prime provides fast, certified, and scalable solutions.