How to Choose a Reliable Metal Stamping Parts Manufacturer: Key Factors That Guarantee Quality & On-time Delivery?

I have missed seasons from late trucks and bad batches. I learned the hard way. Now I buy with proof, not promises.

Choose a stamper that proves coil-to-carton control: prototype first, lock PPAP Level 3, hold Cpk ≥ 1.67 on criticals, publish OEE, and show ISO-backed traceability with ship-to-stock logistics.

I will show the exact checks I run today as a buyer and as a factory. I link each step to our live practice at Prime so you can reuse it on your next RFQ and stop surprises before they start.

Material Options in Metal Stamping: Steel, Aluminum, Stainless, and Their Performance Impact?

Wrong coil specs once doubled my burrs and killed a launch week. That mistake taught me to match metal to press, die, and oil before I touch price.

Confirm yield, elongation, and grain direction; size press to shear strength; pick anti-galling oils for aluminum; plan springback controls for stainless; and trace every heat-lot from receiving to carton.

I start with function, then process. I pull mill certs, I lock grain arrows on the print, and I tune clearance to material strength. The right coil plus the right oil prevents scrap later. For a quick scan of what we build and how we run stamping jobs, see Metal Stamping Parts and our category explainer Stamping Parts. If you want to talk material or coating early, send drawings through Contact and I will return a strip concept with the tonnage math.

Dive deeper Paragraph

What I verify before quoting

- Grade, standard, and acceptable substitutes (AISI/EN/JIS).

- Yield/tensile and elongation windows that affect form and coin.

- Grain direction relative to bends/ribs; burr side callout.

- Coil width, ID/OD, camber limit, splice count; lube compatibility with paint/anodize.

- Heat-lot traceability tied to labels and WMS; barcode fields we print on cartons.

Quick material selection table

| Material | Typical Yield (MPa) | Elongation (%) | Formability | Lubrication Note | Common Pitfalls |

|---|---|---|---|---|---|

| Low-carbon steel (A1008/DC01) | 140–280 | 28–40 | High | General EP oil | Scale, coil set, rust risk |

| HSLA (340–550) | 300–550 | 18–28 | Medium | Higher EP | Springback, higher tonnage |

| 3003/5052 Al | 55–200 | 10–25 | Med-High | Anti-galling | Galling, denting |

| 6061-T6 Al | 240+ | 8–12 | Low-Med | Anti-galling, larger radius | Bend cracks |

| 304/301 SS | 200–400 | 30–45 | Medium | Cl-free high EP | Springback, work hardening |

| 430 SS | 250–450 | 20–30 | Medium | High EP | Edge chipping |

Press tonnage quick checks

Tonnage ≈ Perimeter × Thickness × Shear Strength × Factor (0.7–1.0) + stripping + form peaks. I never book a press without ≥ 30% headroom. For examples and cost levers tied to press choice, see How can I cut total cost for precision stamped metal parts? and the process map on Metal Stamping Parts.

Where I stash the receipts

All certs and lot IDs live in the batch packet and match our box labels. You can audit this flow on real programs by asking through Contact; we keep labeling aligned with shipping pages in product families like Cylinder Components and Metal Casting Parts.

Why Prototyping and Tool & Die Design Are Critical for Cost and Precision?

I once skipped a soft tool to “save time.” The first hard die looked fine, then hole positions walked after forming. We paid for it twice.

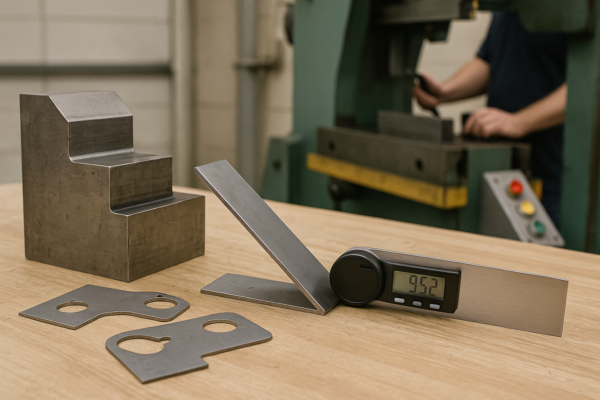

Prototype with soft tools to prove sequence and edge quality; choose D2 or PM-M4 by volume and material; design spare inserts; and maintain each die by hits, not by “feel.”

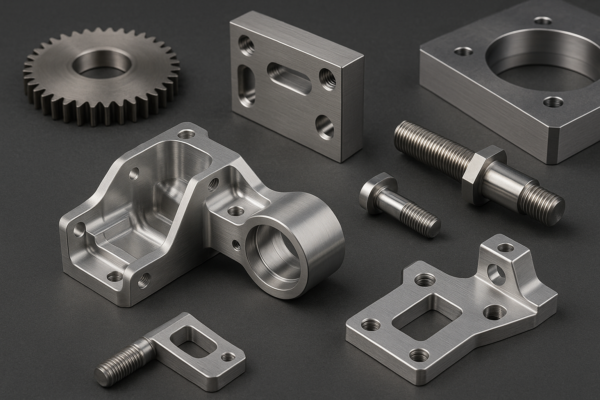

I run a quick tryout with laser blanks and form blocks. I map hole roundness and burr height before and after forming. I log angle drift as the tool warms up. These notes decide the strip layout, not CAD alone. I attach the mini-report to the quote. The result is smoother launch and fewer surprises. For how we support quick corrections during launch, review our core Metal Stamping Parts page and adjacent processes such as Welding Parts and CNC Parts when assemblies need fixtures or tapped holes.

Dive deeper Paragraph

Strip layout rules I refuse to skip

- Pierce before form when possible to keep holes round.

- Add pilots and relief; schedule re-strike for flatness/profile.

- Protect carriers; balance stations to control pitch growth at rate.

- Sensor the tool: misfeed, part-out, slug-detect.

- Publish setup sheet and hit counter on the die for every shift.

Tool steel choices that pay back

| Steel | Wear | Toughness | Best For | Notes |

|---|---|---|---|---|

| O1 | Low | Med | Low volume soft steels | Easy machine; short life |

| A2 | Med | Med | Mixed jobs | Good toughness |

| D2 | High | Med-Low | Mild/HSLA medium runs | Watch chipping in SS |

| PM-M4 | Very High | Med | Abrasive SS, long runs | Excellent edge life |

| Carbide inserts | Extreme | Low | Small pierce wear zones | Use as inserts only |

Maintenance by hits (example)

| Station | Interval (hits) | Action | Symptom if Late |

|---|---|---|---|

| Pierce punches | 80k–120k | Sharpen/replace | Burr height creep |

| Form cam | 150k–200k | Inspect wear pads | Angle drift, galling |

| Coin station | 60k–80k | Polish/check heat | Haze, coin-depth shift |

| Pilots | 200k | Inspect/replace | Position scatter |

If you want a live die-log example and service plan we use on production tools, ask through Contact and I will share a redacted page.

Tolerance Standards and Dimensional Accuracy You Should Demand from a Supplier?

I used to write ± 0.05 mm everywhere. It looked safe. It raised cost and did not hold on forms.

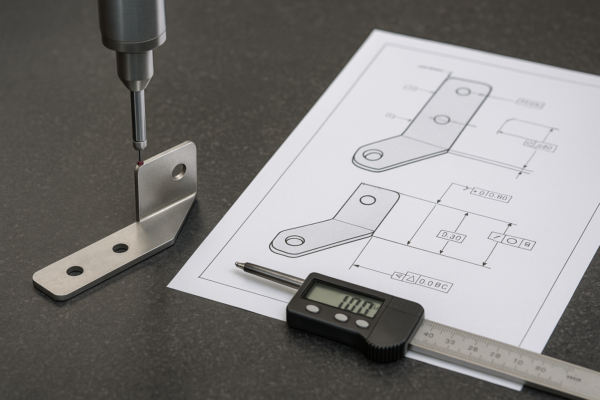

Set tolerances to process capability: Cpk ≥ 1.67 on criticals and ≥ 1.33 on standards; run SPC at the press; align GD&T to assembly; and keep gauge R&R ≤ 10% on criticals.

I define datums the assembly actually sees. I put true position on holes that locate mating parts. I use profile for formed skins. I keep press checks simple and frequent. For the stats behind capability and control charts, the U.S. NIST Engineering Statistics Handbook is my reference. For drawing language, I align to ASME Y14.5.

Dive deeper Paragraph

Capability and MSA targets I hold

| Feature | Typical Tolerance | Capability Target | Gauge R&R |

|---|---|---|---|

| Hole Ø ≤ 10 mm | ± 0.05–0.10 mm | Cpk ≥ 1.67 | ≤ 10% |

| Bend angle | ± 0.5–1.0° | Cpk ≥ 1.33 | ≤ 10–20% |

| Flatness on formed tab | 0.2–0.5 mm/100 mm | Cpk ≥ 1.33 | ≤ 10–20% |

| True position (pattern) | 0.2–0.5 mm @ MMC | Cpk ≥ 1.67 | ≤ 10% |

| Burr height | ≤ 0.05–0.10 mm | Cpk ≥ 1.67 | ≤ 10% |

I tie each SPC point to a station and a reaction plan. Operators adjust only by defined shims or offsets, not by guess. We snapshot PPAP runs at planned rate and attach raw data inside the pack. For definitions and templates, I point teams to ISO 9001 and AIAG PPAP so we all speak the same language.

Lead Time, Logistics, and Certifications: The Real Signs of a Reliable Manufacturer?

My worst miss came from a pretty plan and a blind lane. Customs stalled a perfect build. Shelves filled with the next wave before trucks arrived.

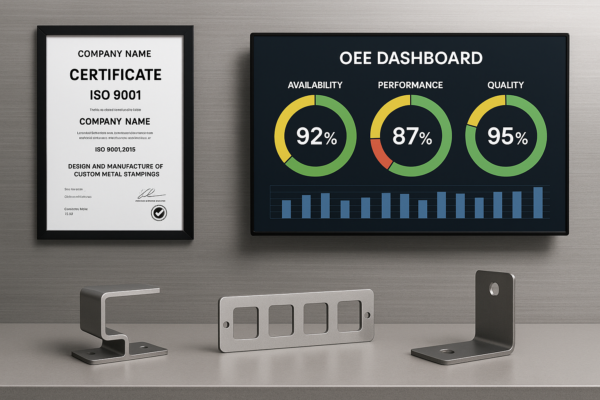

Trust suppliers who show ISO/IATF certificates, PPAP Level 3 history, maintenance-by-hits, in-house response, published OEE, and a ship-to-stock plan with tested packaging and realistic transit buffers.

I check certificates and dates. I pull a past PPAP from a similar part. I follow one shipped box number back to a heat-lot. I ask for the die maintenance board. I verify the pack with a drop test. I confirm Incoterms and HS codes. You can preview how we plan builds and lanes through core pages such as Metal Stamping Parts, adjacent processes like Metal Casting Parts and Welding Parts, then open a lane via Contact.

Dive deeper Paragraph

PPAP Level 3 contents I expect

| Element | Why it matters | What good looks like |

|---|---|---|

| Process Flow + PFMEA | Risk is visible | Real controls tied to causes |

| Control Plan | Actions are clear | SPC points at the press, reaction rules |

| Dimensional Report | Fit is proven | 30-piece run at rate, raw data attached |

| MSA (Gauge R&R) | Data is trusted | ≤ 10% on criticals |

| Capability (Cpk/Ppk) | Stability is shown | Cpk ≥ 1.67 on criticals |

| Material Certs | Traceability | Heat-lot IDs match labels and WMS |

| PSW + Samples | Final sign-off | Samples match reports and pack photos |

Lead time expectation (typical ranges)

| Phase | Days | What I verify | Risk & buffer |

|---|---|---|---|

| RFQ → PO | 7–14 | Scope, DFM questions | Avoid re-quotes with a checklist |

| Tool design & build | 20–45 | Strip layout, steel order | Freeze rev; stock inserts |

| Tryout & PPAP | 10–20 | Run at rate, Cpk data | Plan one correction loop |

| Production & pack | 3–10 | OEE, labels | Drop/vibration tests |

| Transit (ocean) | 25–40 | Booking, docs | Peak season +1–2 weeks |

| Transit (air) | 3–7 | HS code, cartons | Gap fills only |

From standards to lanes

We maintain ISO systems and follow IATF practices on control plans. See the official standards here: ISO 9001, IATF Global Oversight, and PPAP rules from AIAG. If your team wants a neutral primer for new engineers, Wikipedia: Stamping (metalworking) helps with baseline terms.

System Playbook: From RFQ to Carton Without Drama

Short version: I reduce risk by standardizing inputs, measuring the path, and securing lanes before volume.

RFQ inputs I require

- Drawings with rev/date; 3D model + DXF flat.

- Material grade and yield/elongation windows; grain arrow; burr side.

- Annual volume and seasonality; cosmetic class and finish.

- Critical features with Cpk targets and gauge list.

- Pack spec with label fields and photos.

Upload these via Contact — we return a strip concept, tonnage check, and a draft control plan.

Cost drivers you must see (and how I cut them)

| Cost Block | Driver | How I reduce it | Where to see it |

|---|---|---|---|

| Tooling | Stations, steel, inserts | Modular design; soft-tool proof | Metal Stamping Parts |

| Material | Grade, thickness, scrap | Tight nesting; coil width fit | Stamping Parts |

| Press Time | Rate, OEE, setup | SMED; balanced stations | Metal Stamping Parts |

| Secondary Ops | Deburr, coin, tap | In-die only when stable | Welding Parts |

| Pack & Freight | Carton spec, mode | Right-size pack; lane choice | Cylinder Components |

| Quality | SPC, PPAP, audits | Standard templates; digital entry | Metal Stamping Parts |

Springback controls that actually hold

| Method | When I use it | Benefit | Trade-off |

|---|---|---|---|

| Over-bend | Simple flanges | Cheap, robust | Angle shifts with heat |

| Draw beads | Deeper forms | Stabilizes strain | Die complexity |

| Re-strike | Profile surfaces | Tight profile | Extra station, time |

Labels that pass an audit

| Field | Format | Where |

|---|---|---|

| Part/Rev | Text + barcode | 4 faces |

| PO & Lot | Text + barcode | 4 faces |

| Heat-lot | Text + barcode | 4 faces |

| Qty/Box | Numeric | Top + face |

| COO/HS Code | Text/number | Face |

FAQs: Buyer Questions I Answer Every Week

What proves “reliable” before I place a PO?

A recent PPAP Level 3 from a similar part, live OEE by press family, maintenance-by-hits board, heat-lot traceability, and ISO/IATF certificates with valid dates. See our production focus at Metal Stamping Parts and reach out via Contact.

How do I choose progressive vs. transfer?

Pick progressive for high-volume, stable carriers; transfer for deep forms or big parts. We compare scrap %, station count, and restraint during DFM. Start at Stamping Parts and send prints via Contact. For a neutral primer, skim Progressive stamping.

What capability targets do you use?

Criticals at Cpk ≥ 1.67, others at ≥ 1.33, and gauge R&R ≤ 10% on criticals. The definitions and chart basics live in NIST’s e-Handbook.

Which standards matter and why?

ISO 9001 builds the system. IATF 16949 adds automotive discipline and customer-specific requirements. AIAG PPAP defines clean submissions. ASME Y14.5 aligns the drawing language.

How do you protect parts in transit?

Right-size cartons with dividers and film, four-side labels, drop/vibration checks, and photo packs. We model this across commodity pages like Cylinder Components and Metal Casting Parts.

Case Snapshot: When Ship-to-Stock Worked on Day 1

I took over a bracket family that had chronic sorting at incoming. We rebuilt the strip to pierce before form, added a re-strike, and moved to PM-M4 punches. We set SPC on hole Ø, bend angle, and burr height. We ran a clean PPAP at rate with Cpk ≥ 1.67 on criticals, locked the pack with a drop test, and launched with a ship-to-stock agreement. Three lots later, the buyer cut incoming to sampling only. The savings beat the tool change cost in one quarter. The path is the same one I lay out here and on Metal Stamping Parts.

Conclusion

Pick the right coil, prove the tool path, set capability-based tolerances, and back it with ISO/IATF systems and honest lanes. That combination delivers on time.

About the Author

I lead stamping programs from RFQ to dock. I earned my scars in the press room, then tool design, then supplier development. I have signed hundreds of Level 3 PPAPs and audited toolrooms on three continents. At Prime, we run metal stamping with support from CNC Parts, Welding Parts, and Metal Casting Parts under one roof and ship with heat-lot traceability. If you want a fast DFM strip layout with a capability plan, send drawings through Contact.

Next step: Upload RFQ / Contact Prime — I will return a strip concept, press-tonnage check, and a draft control plan.