How to Source Custom Precision Stamping Parts from China: Cost, Quality, and Supplier Selection Explained?

Many international buyers want to source custom stamping parts from China, but often face challenges with verifying supplier capabilities, controlling cost, and managing quality risks. To succeed in global sourcing, you need more than price—you need a trusted partner with proven track records, strong engineering, and reliable communication. Leading industrial sourcing platforms such as Alibaba.com, Made-in-China.com, GlobalSources.com, and industry knowledge from ThomasNet.com are essential resources for buyers worldwide.

By choosing a supplier with valid ISO 9001 or IATF 16949 certification, visible process documentation, and real-world export experience, you control your risk and set up your project for success. This guide explains every key step, backed by insights from trusted sites like Engineering.com and TheFabricator.com.

With two decades of B2B procurement experience, I know the value of supplier verification and technical transparency. Below, you’ll find practical checklists, case studies, and real industry resources—making your sourcing journey more efficient and secure.

What to Look for in a Reliable Precision Metal Stamping Supplier

Not all metal stamping factories in China are equal. The most successful buyers use trusted industrial directories like ThomasNet, Kompass.com, or IndustryNet.com to screen for qualified suppliers with long export histories and visible credentials.

When evaluating a supplier, check for RoHS, REACH, ISO, and IATF certificates, and make sure the company is referenced in trusted B2B marketplaces such as Alibaba or Global Sources. Verify they have a real in-house testing lab and PPAP capability for advanced projects. Explore their material traceability systems and check if they’ve published case studies on reputable sites like Hudson Technologies.

| Supplier Criteria | What to Check | Why It Matters |

|---|---|---|

| Export Certifications | ISO, IATF, RoHS, REACH | Global acceptance, risk control |

| Industry Experience | Client list, export years | Proven project delivery |

| Quality Lab | Advanced testing, PPAP, FAI | Lowers risk of rejects, defects |

| Transparency | Video tour, audit, documentation | Verifies legitimacy |

| References | Reviews, repeat clients | Proven reliability, industry trust |

Make use of public certificate databases and global recall records to check for any historical compliance issues.

Customization Capabilities: Logo Marking, Complex Shapes, and Small Tolerance Stamping

Leading suppliers invest in CNC stamping, fiber laser engraving, and advanced progressive dies to support brand logos, unique shapes, and close tolerances. See successful custom projects published on Hudson Technologies or ThomasNet.

Top factories will offer full engineering drawing support, simulation analysis with CAD/CAM software, and provide material certificates for all orders. They demonstrate their finishing range by offering anodizing, zinc plating, powder coating, and other surface options. Small- and large-batch orders are possible with multi-cavity dies.

Look for these must-haves:

- Laser/Stamp Logo Capability for brand protection and traceability

- Tight Tolerance Stamping and CMM reports for assembly compatibility

- Custom raw materials

- Hybrid CNC + stamping parts

Reviewing sample videos or case studies published on YouTube.com or IndustryWeek.com can help you quickly judge real customization abilities.

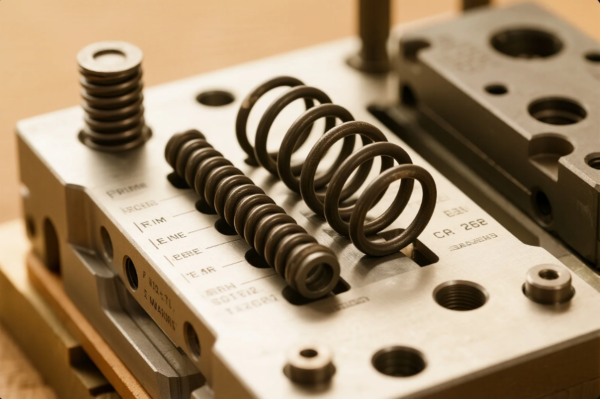

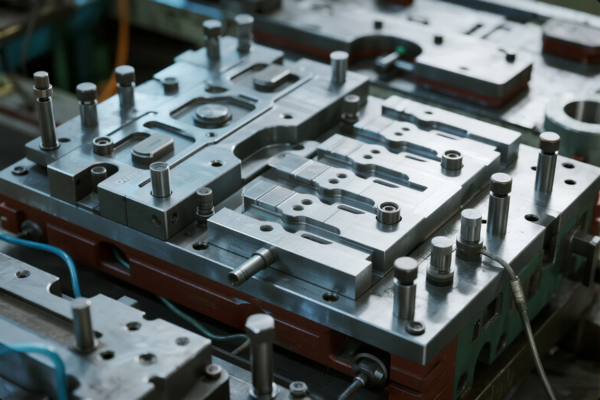

Understanding Stamping Die Design and Its Impact on Product Quality

Tooling is the foundation of precision. The best stamping suppliers use high-hardness tool steels, advanced EDM wire cutting, and regular preventive maintenance. Study the difference between progressive and compound dies for your application.

Expect a good supplier to provide strip layout simulations, maintenance logs, and even CAM machining plans. This lowers your long-term cost and ensures repeatability in mass production.

| Die Design Feature | What to Ask Your Supplier | Why It Matters |

|---|---|---|

| Tool Steel Spec | Grade, hardness, heat treat | Die life, part consistency |

| Maintenance | Regular plan, quick repair | No stoppages, fewer defects |

| Simulation Data | CAD, strip layout, FEA | Optimizes tool trial time |

| EDM/Grinding | Machine list, tolerances | Micro-precision for details |

If your product is new, leverage the technical support and sample evaluation services on EngineeringClicks.com or Protolabs.com.

Case Studies: Successful Custom Stamping Projects in Automotive, Electronics, and More

Thousands of global brands use China’s top stamping suppliers for challenging projects. For example, we supported an automotive OEM with 500,000+ high-strength brackets (zinc plated for rust protection), delivered with full IATF and PPAP documentation.

In electronics, we provided ultra-thin, gold-plated battery contacts for a US device company—using ESD-safe packaging and automated CMM checking. We combined CNC and stamping processes for German machinery customers, always using certified raw materials tracked on Matmatch.com.

| Industry | Project | Prime Solution | Reference Site |

|---|---|---|---|

| Automotive | Brackets, fasteners | Zinc, CMM, PPAP, IATF | automotiveworld.com |

| Electronics | Battery contacts, terminals | Gold, ESD, export packaging | globalspec.com |

| Appliances | Springs, covers, chassis | Laser logo, flexible dies | thomasnet.com |

| Machinery | Gears, hybrid CNC+stamp | CAD, tool steel, hybrid process | industryweek.com |

Check case studies and industry applications for further confidence.

FAQs About Sourcing Custom Precision Stamping Parts from China

Q1: How do I verify a stamping supplier’s credibility?

A1: Always check their ISO and IATF certificates, browse audit resources, and read client reviews on international B2B platforms.

Q2: What is the typical lead time?

A2: Usually 2–6 weeks depending on complexity; get lead time advice on Alibaba.com.

Q3: Can I get technical support and prototyping?

A3: Yes, Prime offers free DFM support, prototyping, and full drawings.

Q4: What are standard payment/shipping terms?

A4: Most clients use T/T, L/C, or PayPal for samples, and Incoterms like FOB or CIF. Exports ship with moisture-proof packaging.

Q5: How does Prime guarantee consistent quality?

A5: We provide inspection reports, PPAP documentation, and accept third-party checks.

Q6: Do you combine CNC machining with stamping?

A6: Yes. Our hybrid process ensures both speed and flexibility.

Q7: Can I visit Prime’s factory?

A7: We welcome virtual and on-site audits.

Q8: What industries do you serve?

A8: Automotive, electronics, appliances, machinery—see Hudson Technologies’ list.

Q9: What about urgent orders?

A9: We offer rush production, maintain tooling for repeats, and apply lean supply practices.

Q10: How do I get started?

A10: Send your drawings and specs through our website or email for a quick response.

Contact Us

For rapid, expert support with your stamping parts, contact Prime today.

Website: https://primecustomparts.com/

Email: [email protected]

Conclusion

Sourcing custom stamping parts from China can be simple and low risk—if you know how to verify, compare, and communicate with your supplier. Choose a certified, transparent partner for lasting quality and on-time delivery. Prime is ready to support your global sourcing success.