Is Laser Cutting Cheaper Than 3D Printing?

Many buyers compare laser cutting and 3D printing when choosing a manufacturing method.

Laser cutting is usually cheaper for flat parts, while 3D printing is better for complex 3D shapes. Each has its cost strengths.

Let’s break down the differences—cost, speed, part design, and profitability—to help you choose the right method for your next project.

Is it cheaper to 3D print or laser cut?

This is a key question we hear from buyers asking about prototyping or small-batch production.

Laser cutting is generally cheaper for 2D parts, while 3D printing is better for complex or hollow structures.

Laser cutting removes material from flat sheets (like carbon steel, acrylic, or MDF). 3D printing builds objects layer-by-layer using plastics or resins.

Cost comparison:

| Feature | Laser Cutting | 3D Printing |

|---|---|---|

| Setup Time | Low (just 2D file) | Moderate (3D CAD + slicing) |

| Material Efficiency | High (nesting sheets) | Lower (support and brim loss) |

| Output Speed | Fast for flat parts | Slow for high-detail models |

| Surface Quality | Smooth and edge-ready | Often needs sanding or polishing |

Check All3DP for further cost insights on typical DIY and industrial-grade equipment.

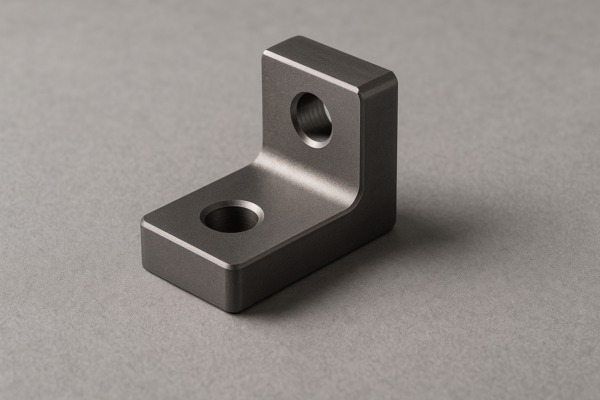

At Prime, we handle both technologies. If your parts are flat, rigid, and functional (e.g., metal brackets or plastic shields), laser is faster and more cost-efficient. For housing prototypes or airflow components, 3D printing makes more sense.

Which is better, a 3D printer or a laser printer?

This comes down to function. Ask: Is my part flat or 3D? Functional or cosmetic?

Laser cutters excel in precision sheet work. 3D printers handle shape complexity that laser systems can’t reach.

Breakdown by use case:

| Task | Best Method | Why |

|---|---|---|

| Engraving logos | Laser cutter | Clean edge and deep contrast |

| Bracket fabrication | Laser cutter | Quick, rigid parts from metal |

| Hollow casing model | 3D printer | Laser can’t form internal chambers |

| Visual prototyping | 3D printer | Visual appeal with high surface detailing |

| Serial number marking | Laser engraver | Batch-run efficiency |

Need both? Prime supports hybrid production. We frequently cut flat parts with laser, then print attachments like housings, handles, or custom spacers in PLA or ABS. See examples in our welding assemblies page.

Also read this Autodesk guide comparing form vs function in both methods.

Is laser cutting expensive?

Some assume laser systems cost more to operate—but it depends on the job.

Laser cutting is cost-effective for medium-to-large volume runs of flat components. It only becomes expensive with thick or exotic materials.

Factors that raise laser cutting costs:

- Material type – Stainless or aluminum reflect heat

- Part geometry – Intricate shapes = more motion and time

- Gas type – Nitrogen or oxygen use raises operating costs

- Thickness – More power = slower cut = more electricity

- Small quantities – Setup time amortizes poorly on low volume

At Prime, we reduce cost through:

- Efficient nesting software (to save raw sheet use)

- Multi-material batch jobs (to reduce setup cost)

- ISO-certified precision (less scrap, better yield)

- Competitive China-based pricing with global delivery

Compared to 3D printing—especially resin SLA types—laser is 25–40% faster per part when dealing with repeatable designs.

Explore more on Laserhub’s cost calculator to estimate unit pricing per material and geometry.

Is 3D printing or laser engraving more profitable?

Buyers and small business owners often ask: which is better for resale?

Laser engraving tends to be more profitable in high-volume consumer or promotional applications. 3D printing has higher margins for custom and low-volume markets.

Business applications comparison:

| Product Type | Profit Method | Why It Works |

|---|---|---|

| Branded wood keychains | Laser engraving | Low cost per unit, batch production |

| Personalized nameplates | Laser engraving | High margin, low labor |

| Prototype parts for R\&D | 3D printing | Premium price for short-run models |

| Gaming figurines | 3D printing | Niche customization, good markup |

| Engraved QR code labels | Laser | Fast output, low materials |

At Prime, we help startups and product brands build laser-engraved packaging, custom tags, and 3D-printed prototype runs. Our engineers can help adjust thickness, engraving depth, and supports to reduce cost and raise margin.

Also, for creative inspiration, browse the Ponoko marketplace—a hub for profitable laser-cut/engraved product ideas.

Conclusion

Is laser cutting cheaper than 3D printing? Often yes, especially for flat parts, large quantities, and fast delivery. But 3D printing is more flexible for curved, low-volume, and iterative designs.

Not sure which is best for your part?

Talk to Prime and get a free drawing review, side-by-side quote, and expert guidance.

- 🌐 Website: https://primecustomparts.com

Whether it’s CNC parts, custom stamping, or laser-ready acrylic sheets—we deliver parts that perform, priced to help you grow.